Industrial gears can simply be used to transfer rotational motion, or the interlocking of gears with unequal diameters can produce a change in rotational speed and rotational force (torque). Gears are used extensively throughout industry, and they are essential to the functioning of many kinds of industrial equipment and products. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gears are what we do best, and we are experts in our field. We have three generations of experience backing our company, and we use all of it to benefit you in any way possible.

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Rempco, we specialize in manufacturing precision gears that meet the highest standards of performance and durability. With decades of experience behind us, we've built a reputation for producing custom and high-precision gearing solutions that serve a broad range of industries, from aerospace and defense to heavy equipment and industrial automation.

Since 1951, Circle Gear and Machine has produced top-quality American and Metric gears. Specializing in small lot production from 1 to 1000 pieces, Circle Gear provides a diverse product line including spur gears, worm gears, bevel gears, helical gears, internal gears and more. We offer a full service manufacturing facility, reverse engineering, and breakdown services for all your gear needs.

Reliance has been a respected gear fabricator for more than 50 years and specializes in high-quality solutions up to a diameter of 33-inches, in addition to those that are straight, conflex, hypoid and zerol in type, as well as many more varieties. Please speak with a friendly professional with any questions you may have or visit Reliance’s website for more information or to request a quote.

More Industrial Gear Manufacturers

Comprehensive Guide to Industrial Gears: Types, Applications, and Buying Insights

Industrial gears are fundamental mechanical components found in countless types of manufacturing equipment. From bevel gears and spur gears to helical gears and worm gears, these precision-engineered products are essential for the transfer of motion and power in a wide range of industries. Whether you are seeking to source gears from manufacturers or evaluate which gear type best fits your application, understanding the fundamentals of industrial gear systems is critical for optimal performance and efficiency.

What are Industrial Gears and Why Are They Important?

Industrial gears are robust mechanical devices designed to transfer rotational motion and torque between machine components. Unlike gears used in commercial or consumer products, industrial gears are engineered for heavy-duty operation, often constructed from high-strength metals such as hardened steel, alloy steel, or specialized cast iron to withstand challenging environments, high loads, and continuous use. Their durability and reliability are crucial in sectors where operational downtime can result in significant losses.

- Automotive manufacturing

- Heavy equipment (mining, oil rigs, construction machinery)

- Food processing plants

- Textile and paper mills

- Aerospace and defense

- Power generation and energy transmission

- Material handling and conveyor systems

In each of these industries, gears are integral to systems requiring precise speed, direction, or torque control. Their reliability is often the backbone of operational safety and productivity.

Exploring Gear Types: Key Varieties and Their Applications

When choosing an industrial gear, it’s important to select the right type for your intended use. Here’s an overview of the most common gear types found in industrial settings:

Spur Gears

Spur gears are the simplest and most widely used type of gear. Also known as straight-cut gears, their teeth are aligned parallel to the gear’s axis, providing straightforward power transmission with high efficiency. Common uses for spur gears include:

- Industrial machines with low-to-moderate speeds

- Conveyor systems

- Automotive transmissions

- Material handling equipment

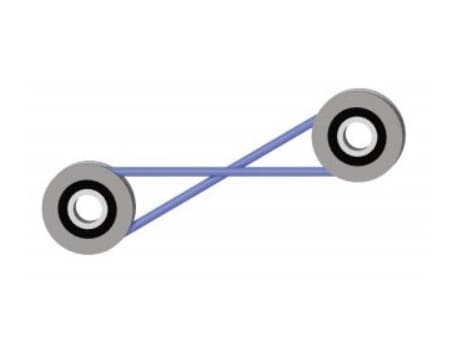

Spur gears are also frequently used as sprockets—thin gears designed to mesh with roller chains. Sprockets act as non-slip pulleys in power transmission, making them ideal for applications such as bicycle chains, conveyor belts, and tank treads.

Helical Gears

Helical gears feature angled teeth, which allows for smoother and quieter operation than spur gears. Their design permits more gradual engagement of teeth, reducing noise and wear. Helical gears are ideal for applications where:

- High-speed operation is required

- Quieter gear operation is desirable

- Greater load-carrying capacity is needed

Common uses for helical gears include automotive gearboxes, industrial mixers, printing presses, and heavy-duty conveyors. Their ability to transmit motion between non-parallel shafts adds to their versatility in complex machinery.

Bevel Gears

Bevel gears are used when the direction of a shaft’s rotation needs to be changed. Their conical shape and angled teeth make them perfect for transmitting motion between intersecting shafts, usually at right angles. Bevel gears are commonly found in:

- Automotive differentials

- Power tools

- Industrial gearboxes

- Printing presses

By allowing power to be transmitted at varying angles, bevel gears provide design flexibility in complex machinery layouts.

Worm Gears

Worm gears consist of a worm (screw-like shaft) and a worm wheel. This gear type enables high reduction ratios and transmits motion at a 90-degree angle. Worm gears are valued for their ability to provide:

- Very high gear reduction in compact spaces

- Self-locking capabilities for safety-critical applications

- Smooth, quiet operation

They are widely used in elevators, conveyor systems, and packaging machinery, as well as in applications where precise, incremental motion is required.

Planetary Gears

Planetary gear systems (epicyclic gears) are more complex arrangements involving a central “sun” gear, multiple “planet” gears, and an outer “ring” gear. This configuration offers several advantages:

- High torque density

- Compact design for space-constrained environments

- Even load distribution across gears

- Multiple gear ratios and operational modes

Planetary gears are commonly used in automatic transmissions, robotics, wind turbines, and precision drive systems where high performance and reliability are paramount.

Splines

Splines are cylindrical shafts or rods with straight, evenly spaced teeth. They transmit torque laterally and are often found in:

- Drive shafts

- Couplings

- Automotive and aerospace assemblies

Splines ensure the secure transmission of power, preventing slippage between coupled components.

How to Choose the Right Industrial Gear: Buyer’s Guide

Choosing the right gear for your industrial application is essential for performance, longevity, and cost-effectiveness. Here are key factors to consider when evaluating or purchasing gears:

- Load Requirements: What are the maximum torque and power demands? Consider peak and continuous loads.

- Speed: What is the desired input and output speed? High-speed applications may require special gear materials or lubrication.

- Direction of Motion: Do you need to change the direction of rotation or transmit power between non-parallel shafts?

- Space Constraints: How much installation space is available? Compact gear types (like planetary gears) may be preferable in tight spaces.

- Environmental Conditions: Will the gears operate in high temperatures, corrosive environments, or areas with abrasive materials?

- Noise and Vibration: Does your application require quiet operation?

- Maintenance Requirements: How accessible are the gears for inspection and lubrication?

- Budget: What is your budget for both initial purchase and long-term maintenance?

Need help selecting the right gear type for your machinery?

Explore our comprehensive directory of gear manufacturers or contact our experts for personalized recommendations tailored to your industry and operational needs.

Industrial Gear Materials: What to Know

Material selection is a critical factor in gear performance and longevity. Industrial gears are typically manufactured from:

- Hardened Steel: Offers excellent strength, wear resistance, and fatigue life. Ideal for heavy-duty and high-load applications.

- Alloy Steel: Enhanced properties for toughness and corrosion resistance. Commonly used in automotive and aerospace gears.

- Cast Iron: Good damping properties and cost-effective for large, low-speed gears.

- Bronze and Brass: Used for worm gears and applications requiring reduced friction.

- Advanced Composites: Lightweight and non-corrosive, suited for specialized or high-speed uses.

Choosing the right material can reduce maintenance costs, increase operational efficiency, and extend the life of your equipment.

Benefits of High-Quality Industrial Gears

Investing in premium-quality gears yields numerous operational and economic benefits:

- Enhanced reliability – Reduce unexpected downtime and costly repairs

- Increased efficiency – Minimize energy losses and maximize power transmission

- Longer service life – Durable materials and precise engineering extend gear lifespan

- Smoother operation – Precision manufacturing reduces noise and vibration

- Safety improvements – Properly engineered gears lower the risk of mechanical failures

Common Use Cases and Industry Applications

Gears are essential for the movement, control, and automation of mechanical systems. Here are some typical applications:

- Automotive transmissions and drivetrains: Allow for variable speed and torque delivery to wheels

- Heavy mining equipment: Transmit high torque for crushing, drilling, and material transport

- Food and beverage processing: Enable precise movement in conveyors, mixers, and bottling lines

- Textile and paper manufacturing: Drive rollers, cutters, and spindles for continuous operation

- Energy and power generation: Transfer rotational motion in turbines, generators, and windmills

- Material handling systems: Power belt conveyors, lifts, and automated guided vehicles

Industrial Gear Manufacturing: Processes and Quality Considerations

Gear manufacturing is a precision-driven process involving:

- Design and prototyping: Advanced CAD software and simulation tools ensure perfect fit and function

- Material selection: Based on load, speed, and operating environment

- Cutting and forming: Methods include hobbing, shaping, broaching, and grinding for accurate tooth profiles

- Heat treatment: Hardens gears for wear resistance and strength

- Quality inspection: Precision measuring tools and non-destructive testing verify compliance with standards (such as AGMA, ISO, DIN)

When sourcing gears, always inquire about the manufacturer’s quality control processes, certifications, and experience in your industry. This reduces the risk of defects and ensures reliable, long-term performance.

FAQs: Industrial Gear Selection, Customization, and Maintenance

- Q: How do I determine which gear type is best for my application?

- A: Assess your torque, speed, and space requirements. Consult with gear manufacturers for expert guidance, especially for complex or high-performance environments.

- Q: Can gears be customized for unique machinery?

- A: Yes. Many gear suppliers offer custom engineering services, including tailored tooth profiles, materials, and coatings to meet specialized needs.

- Q: What maintenance do industrial gears require?

- A: Regular inspection for wear, proper lubrication, and alignment checks are essential. Proactive maintenance extends gear life and prevents unscheduled downtime.

- Q: What are signs of gear failure?

- A: Common indicators include increased noise, vibration, overheating, and visible wear or pitting on gear teeth. Address issues promptly to avoid costly damage.

- Q: How can I optimize efficiency and lifespan of my gear systems?

- A: Use high-quality materials, ensure precise installation, maintain proper lubrication, and schedule routine inspections. Consider working with experienced gear manufacturers for ongoing support.

Ready to Source or Upgrade Industrial Gears?

Industrial gears are at the heart of countless mechanical systems, powering everything from factory automation to heavy earth-moving equipment. By understanding gear types, applications, and purchase criteria, you can make informed decisions that enhance your facility’s productivity, efficiency, and safety.

- Looking for a trusted industrial gear manufacturer? Start your supplier search here.

- Need a custom gear quote? Request a quote now for rapid turnaround and expert advice.

Whether you are specifying gears for a new project or upgrading existing machinery, leverage the expertise of experienced gear manufacturers to ensure your gears meet the highest industry standards for performance and longevity.

Industrial Gear Trends and Innovations

Today’s gear industry is evolving rapidly, with OEMs and end-users demanding greater efficiency, digital integration, and sustainability. Key trends include:

- Smart gears: Integration of sensors for real-time monitoring of temperature, vibration, and wear

- Advanced materials: Use of composites and surface treatments for weight reduction and corrosion resistance

- Precision manufacturing: CNC machining and 3D printing enable highly customized gear geometries

- Predictive maintenance: IoT-enabled gearboxes alert operators before failures occur

- Eco-friendly processes: Sustainable manufacturing and recyclable materials to meet environmental standards

Conclusion: Making the Right Choice in Industrial Gears

Industrial gears are a critical investment for any operation that relies on mechanical motion and power transmission. By choosing the right gear type, material, and manufacturer, you secure the foundation of your machinery’s performance and reliability. For further assistance, browse our gear manufacturer directory, request expert consultation, or explore our technical resources to ensure you make the most informed and cost-effective gear selection for your business.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services