Drive shafts could not function without splines. Drive shafts are used to transmit torque from an engine to the wheels of a vehicle, but drive shafts are also widely used in other industrial processes and even in some consumer products. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gears are what we do best, and we are experts in our field. We have three generations of experience backing our company, and we use all of it to benefit you in any way possible.

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Rempco, we specialize in manufacturing precision gears that meet the highest standards of performance and durability. With decades of experience behind us, we've built a reputation for producing custom and high-precision gearing solutions that serve a broad range of industries, from aerospace and defense to heavy equipment and industrial automation.

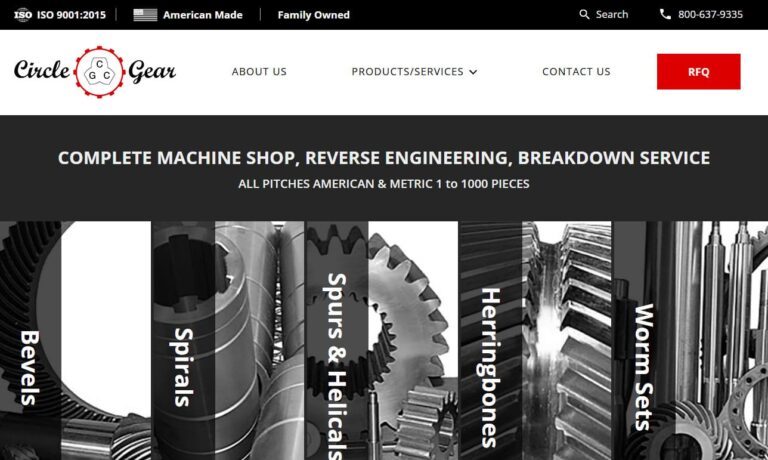

Since 1951, Circle Gear and Machine has produced top-quality American and Metric gears. Specializing in small lot production from 1 to 1000 pieces, Circle Gear provides a diverse product line including spur gears, worm gears, bevel gears, helical gears, internal gears and more. We offer a full service manufacturing facility, reverse engineering, and breakdown services for all your gear needs.

Reliance has been a respected gear fabricator for more than 50 years and specializes in high-quality solutions up to a diameter of 33-inches, in addition to those that are straight, conflex, hypoid and zerol in type, as well as many more varieties. Please speak with a friendly professional with any questions you may have or visit Reliance’s website for more information or to request a quote.

More Spline Gear Manufacturers

In an automobile, the energy generated by the combustion reaction in the engine's cylinder forces the movement of a piston, which is connected to a rod, which eventually transfers rotational motion to the drive shaft and other industrial gears. The drive shaft would not be able to connect to other rotational motion transmission equipment without splines.

Splined gears serve similar purposes in motorized watercraft and other vehicles. In a spline gear, a male spline attached to a shaft meshes with a female spline, equalizing the rotational speed. Spline gears can be, in terms of their spline shape, nonhelical, involute, or straight-sided. Spline shape contributes to the gear's durability and operation qualities.

Teeth quantity, pitch diameter, face width and length all contribute to spline gear performance. The pitch of spline gears is determined by the number of teeth and the preferred pitch diameter. Another important factor to consider is the material of construction, as different spline gear composition materials perform differently under different circumstances. Factors that contribute to optimal spline performance are its power transmission requirements, heat generation and the presence of corrosive elements.

Spline gears can be made of aluminum, brass, bronze, cast iron, steel and even plastics like nylon and polycarbonates. Spline gears may also be made with a combination of metal and plastic. Splines can also be designed for use in small motors. Fans, space heaters, pumps and other small motors require a means by which the energy generated in the motor can be transferred to other moving parts. Splines provide the first avenue by which that torque can be transmitted to other moving parts. Such splines are very small and tend to vary in terms of their composition much more than do splines applied in automotive or other heavy-duty equipment contexts.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

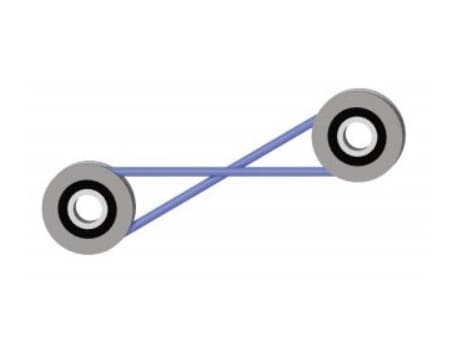

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services