More Industrial Gear Manufacturers

Industrial Gear Applications

Industrial gears are the unsung heroes powering countless machines and industries. Their applications are incredibly versatile, spanning everything from adjusting speed and power transmission to managing motion, reducing force, and ensuring mechanical efficiency. Industrial gears are crucial in industries such as automotive manufacturing, aerospace engineering, railway systems, heavy equipment, mining, transportation, food and beverage production, energy, and material handling.

You’ll find precision-engineered gears in cars and trucks (transmissions, differentials, power steering), gear motors for robotics and automation, bicycles and motorcycles, airplanes (actuators, landing gear systems), conveyor systems, wind turbines, packaging machinery, and countless other critical applications. The adaptability of industrial gears makes them foundational for any process that requires the reliable transfer of torque, speed, or direction of motion.

Are you researching the right gear type for your machine? Explore our comprehensive breakdown below or browse top industrial gear manufacturers for custom solutions.

The History of Industrial Gears

For millennia, humans have crafted gears, with some of the earliest examples originating in 4th century BC China, now showcased at the Luoyang Museum in Henan Province. Remarkably, the first differential gear, dating back to the first millennium BC, was also a Chinese innovation. This ancient gear was part of a south-pointing chariot, an ingenious invention by engineer Ma Jun, who lived between 220 and 265 BC. By 725 AD, Chinese engineers had advanced their skills to create the first geared mechanical clocks, marking a significant milestone in engineering history.

The earliest European gears date back to between 150 and 100 BC, originating from the Antikythera mechanism, an ancient Greek device used to predict astronomical events. Around 50 AD, Hero of Alexandria, a mathematician and engineer, documented gear construction in Roman Egypt. His knowledge stemmed from the Alexandrian school of thought in the 3rd century BC. Archimedes, the renowned Greek polymath who lived from 287 to 212 BC, also significantly influenced early European gear manufacturing.

In the medieval Middle East around 1206 AD, the ingenious Arab engineer Al-Jazari devised the segmental gear, a marvel that transferred reciprocating motion to and from a cogwheel. Over in the Indian subcontinent, spanning the 13th to 14th centuries, the worm gear emerged, revolutionizing the operation of roller cotton gins. At the same time, in medieval England, Richard Poore and Elias of Dereham crafted the Salisbury Cathedral clock. Completed in 1386, this intricate geared mechanical clock remains a functioning testament to their craftsmanship.

Gears became essential during the Industrial Revolution, driving the surge in machine usage and automation. The arrival of steam power, locomotives, and mass production lines demanded robust, durable gears to propel trains and industrial machinery. From that point on, the significance of gear machining, gear cutting, and gear manufacturing has only continued to grow as industries evolved.

Modern gears draw inspiration from their historical counterparts, yet they surpass them in versatility and utility. Today’s gears are stronger, more compact, and can be crafted from a wide range of materials, including advanced plastics and high-performance alloys. Advances in CNC machining, hobbing, and precision engineering allow for unprecedented accuracy and repeatability in industrial gear manufacturing, setting them apart from the gears of the past. These innovations have enabled the rise of custom gears for specialized applications, supporting evolving industries such as robotics, renewable energy, and automated production.

Industrial Gear Design

Production

To endure the rigors of constant use, industrial gears benefit from advanced cutting and manufacturing techniques such as gear hobbing, gear shaping, broaching, grinding, and milling. By pairing gears of different sizes and tooth profiles, manufacturers can precisely adjust shaft rotational speeds and torque transmission to fit specific requirements. High-quality gears are typically heat treated and surface-finished for enhanced wear resistance and durability. Lubrication systems—such as gear oil baths and automatic lubricators—are also essential to minimize friction, reduce heat, and prolong operational life. With proper engineering and maintenance, industrial gears deliver unmatched performance and reliability in even the harshest working environments.

Materials

Gears can be crafted from various materials selected for their intended use, load capacity, and environmental conditions. Typically, metals or durable industrial plastics are used. In the automotive industry, robust metals such as hardened steel, alloy steel, copper, brass, and titanium are preferred for their strength, wear resistance, and ability to withstand high torque and stress. For machinery requiring lightweight components or corrosion resistance—such as in food processing or chemical plants—engineers may select plastic gears made from high-performance materials like polycarbonate, nylon, acetal (Delrin), or PEEK. Hybrid designs that combine metal and plastic elements are also increasingly popular for applications requiring specific performance characteristics.

Considerations

When manufacturers design industrial gears, they meticulously select the number of teeth, gear module, pitch diameter, pressure angle, and gear ratios, knowing these choices will affect the gear’s durability, strength, speed, noise, vibration, and control within a larger assembly. Factors such as operating temperature, lubrication method, backlash, and mounting position are also considered to ensure optimal performance. By employing the previously discussed production techniques—and leveraging advanced CAD/CAM software—manufacturers can create custom gears tailored to any application, from high-speed, low-torque settings to heavy-duty power transmission systems.

What is a gear ratio? The relationship between gear size and speed is known as the speed ratio or gear ratio. This ratio is calculated using the number of teeth on each gear. For example, if two interlocking gears have 60 and 30 teeth respectively, the gear ratio would be 2:1. Gear ratios are critical for applications where precise speed and torque adjustments are required, such as in conveyor drives, automotive transmissions, and industrial machinery.

Types of Industrial Gears

The realm of industrial gears is incredibly diverse. Among the many types, you can find spur gears, gear sprockets, planetary gears, bevel gears, spline gears, helical gears, rack and pinion gears, worm gears, differential gears, hypoid gears, and more. Each type offers unique advantages for specific mechanical functions and industrial requirements.

- Spur Gears: Spur gears, often known as straight-cut gears, are the most basic and widely used type. They feature straight sides along the gear wheel’s axis and teeth aligned parallel to this axis. Spur gears are essential in applications requiring simple, efficient power transmission, such as conveyor belts, gearboxes, and speed reducers. They are also commonly used as sprockets and key components in planetary gear systems.

- Gear Sprockets: Sprockets are slender gears with easy-locking teeth engineered to engage seamlessly with roller chains, similar to those found on bicycles and conveyors. Sprockets are designed for reliable, non-slip pulley power transmission and are essential in material handling, agriculture machinery, and packaging equipment.

- Planetary Gears: Planetary gears, also known as epicyclic gear trains, are central to sophisticated systems needing seamless torque transfer and compact design. Their configuration includes a “sun gear” at the center, surrounded by “planet gears” that orbit around it within a ring gear. Planetary gear systems are found in automatic transmissions, wind turbines, robotics, and heavy-duty equipment.

- Spline Gears: Spline gears are cylindrical or rod-shaped gears with straight teeth that allow them to transmit motion laterally by fitting inside internal devices or gears. They are widely used for coupling shafts and transmitting torque in automotive, aerospace, and industrial machinery applications.

- Helical Gears: Helical gears are known for their high-speed rotation and ability to handle substantial loads. Their teeth are angled in a helix around the shaft, which provides smoother and quieter operation compared to spur gears. Helical gears are favored in automotive transmissions, compressors, and high-performance machinery that encounter both radial and thrust loads.

- Rack and Pinion Spur Gears: Rack and pinion systems consist of a rack (a straight toothed bar or rod) meshed with a pinion (a small gear). When the pinion turns, it moves the rack in a straight line, transforming rotational torque into linear force. Rack and pinion mechanisms are widely used in rack railways, CNC machines, and automobile steering systems for precise control.

- Worm Gears: Worm gears are unique helical gears characterized by a steep helix angle (nearly 90 degrees) and an elongated body, resembling a screw. Worm gears are prized for their high torque, low-speed gear ratio, as well as their simplicity and compact design. They are often used in conveyor systems, elevators, and heavy machinery for load holding and smooth, quiet operation.

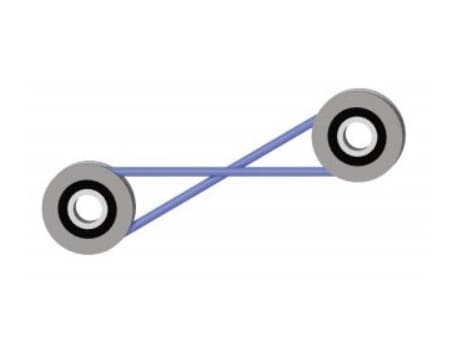

- Differential Gears: Differential gears consist of two shafts that can be independently adjusted in both angle and direction. These gears are engineered to mesh and operate together at a controlled speed to generate a specific amount of torque. Differentials are critical in vehicles, allowing wheels to rotate at different speeds when cornering.

- Bevel Gears: Bevel gears, with their conical design, interlock with other gears at right angles, making them ideal for transmitting torque to rear wheels or changing the axis of rotation. They can have either straight or curved teeth (the latter known as spiral bevel gears). Bevel gears are popular in automotive, mining, packaging machinery, and material handling systems.

Not sure which gear type is right for your application? Contact a gear manufacturer for expert guidance or see our detailed guides for each gear type.

Bevel Gears: How They Work

Bevel gears, featuring two conical toothed wheels, efficiently transfer power between intersecting axes—usually at a 90-degree angle. Their effectiveness and reliability make them a staple in engineering sectors like automotive, control systems, power plants, manufacturing machinery, and mining equipment.

Bevel gears come in various types, primarily distinguished by their configuration angles, with the 90° angle being the most prevalent. Typically, these gears are housed within a gearbox or differential, allowing for efficient torque transfer and directional changes. Their design allows for compact, space-saving installations in mechanical systems.

Types of Bevel Gears

There are various kinds of bevel gears, but the most prevalent are the straight bevel gear and the spiral bevel gear. The key distinction between these two lies in their geometric design, which directly impacts their efficiency, noise, and load-handling capabilities.

Straight bevel gears are the most straightforward type of gear, with straight teeth that allow for direct contact between the gear and pinion. They are widely used in automotive differentials, power tools, manual gearboxes, and agricultural equipment.

Straight bevel gears offer several advantages:

- Ease of Manufacturing: Their simple design makes them straightforward to produce, allowing for cost-effective production and quick turnaround.

- Direct Instantaneous Contact: They have direct lines of contact, allowing for greater tolerance in mounting and easier alignment in assemblies.

While the significant drawbacks include:

- Slow speed and immobility: Straight bevel gears are not well-suited for high-speed applications due to increased noise and wear.

- Vulnerability to sudden impacts or shock loads, potentially causing gear breakage.

- Excessive vibration and noise, especially at higher speeds.

Spiral bevel gears are more complex due to their curved teeth, necessitating a specialized manufacturing process to create them. Their helical design allows for smoother engagement and quieter operation.

Spiral bevel gears offer several benefits:

- They can handle greater axial thrust and load sharing because of their spiral design, which allows for directional changes and higher efficiency under load.

- Their spiral geometry reduces noise and vibration, making them ideal for automotive transmissions and high-speed machinery.

- They provide smoother operation due to gradual engagement and disengagement, reducing wear and improving reliability.

However, there are significant drawbacks to consider:

- Elevated manufacturing costs arise from the necessity of specialized equipment, like CNC machining, to create precise parts.

- Compatibility challenges: The parts aren’t interchangeable as each one is uniquely designed and matched to its mate.

Curious about which bevel gear best fits your needs? Speak with a gear specialist to discuss application-specific requirements, load demands, and customization options.

Factors in Choosing the Appropriate Bevel Gear

As previously discussed, every type of bevel gear comes with its own set of pros and cons. It’s important to weigh these aspects before making a purchase or specifying a gear for your system. The simplest method to decide which type to buy is to start by examining its intended use and the operational demands of your machinery.

- Automotive: If you’re seeking a bevel gear for automotive use, consider a spiral bevel gear or angular gearbox. These options offer a compact design with high efficiency while ensuring a low noise level, making them ideal for vehicle differentials and high-performance drivetrains.

- Industrial Machinery: For industrial applications requiring bevel gears—such as reliable gear transmission with a compact structure—the Hansen industrial gearbox (straight bevel) is an excellent choice. This gearbox offers robust transmission power, capable of delivering torque ranging from 36,000 Nm to 1,200,000 Nm, and can be customized to meet specific industrial requirements. Its versatile applications span packaging machinery, chemical equipment, metallurgical mining equipment, steel power equipment, road construction machinery, and the building materials industry.

- Heavy Equipment: Straight bevel gears are crucial components in heavy machinery, serving various purposes such as propulsion, similar to the automotive differential system. This crane gearbox boasts numerous features, including an optimized distance and transmission ratio tailored for crane operations like loading and unloading materials. Made from high-quality alloy steel, the parts are easily interchangeable due to their straight bevel design, simplifying replacement if components become defective. These gears find applications in metallurgy, mining, construction, and other heavy industrial sectors.

Need help specifying the optimal industrial gear for your project? Request a quote or technical consultation from leading gear manufacturers.

Industrial Gear Accessories

To optimize system performance and ensure reliability, a variety of industrial gear accessories and auxiliary components are available. Typical gear accessories encompass:

- Handwheels: Manual control devices for adjusting gear settings or positions.

- Stem protectors and stem nuts: Provide protection and secure attachment points for gear assemblies.

- Miter boxes: Support bevel and miter gear applications by housing gears at precise angles.

- Gear housings: Enclosures that safeguard gears from contaminants and provide structural support.

- Gear lubricants and gear oils: Specialized fluids designed to minimize friction, heat, and wear.

- Temperature monitors: Sensors and gauges to detect overheating and prevent gear failure.

- Lug drives: Keyed mechanical devices for transmitting torque between shafts and gears.

- Seals, shrouds, and guards: Additional measures to enhance gear protection and safety.

Are you outfitting a new gearbox or upgrading your system? Consider these essential accessories to maximize uptime and minimize maintenance costs.

Proper Care for Industrial Gears

Proactive maintenance is the key to ensuring your industrial gears stay in top shape and deliver a long, productive service life. Here are best practices for industrial gear care:

Read Labels

Always review the labels and technical documentation provided with your gearbox or gear set. Verify ratings for torque, speed, and load capacity to ensure compatibility with your application. Keeping records of maintenance schedules and manufacturer recommendations is vital for warranty compliance and optimal performance.

Limit Dust Contact

Floating dust and particles can wreak havoc on your gears if left unchecked, leading to abrasive wear and premature failure. Minimize dust and pollution in your production facility by implementing air curtains, industrial vacuum systems, and dust management protocols. These measures not only improve air quality but also prevent contaminants from reaching gearboxes, bearings, and other sensitive components.

Limit Fluid Contact

Preventing liquids—including water, lubricants, and chemicals—from contacting your gears is critical. Unchecked leaks or exposure can lead to corrosion, rust, and costly system malfunctions. Regularly inspect shaft seals, gaskets, and housings to ensure they are intact. Promptly address any leaks to avoid increased fuel or lubricant costs and impaired gear performance.

Lubricate Your Gears

Effective lubrication is essential for minimizing friction, dissipating heat, and preventing excessive wear. Regularly apply the appropriate gear oil or grease as specified by your manufacturer. Using the wrong lubricant can cause chemical incompatibility, so always consult your gear supplier or maintenance manual for guidance. Automated lubrication systems are recommended for high-duty or hard-to-access gear assemblies.

Do Not Allow Overheating

Overheating can lead to a host of issues including poor performance, excessive strain, and contamination of the gear shaft or teeth. Make it a habit to regularly inspect gearboxes and engines for signs of overheating. Use temperature monitoring devices and thermal imaging when possible, and ensure adequate ventilation and cooling within enclosures.

Looking to extend gear lifespan and reduce downtime? Schedule regular inspections, adhere to maintenance best practices, and consult your manufacturer for advanced preventive measures.

Industrial Gear Standards

Just like other industrial machinery, the standards for your gears vary based on your industry, application, and geographic location. For instance, if you’re operating within the food production sector in the United States, your gears must meet FDA approval for sanitary design and materials. In environments where safety and quality are paramount, industry-specific certifications and compliance standards are essential.

In the United States, the American Gear Manufacturers Association (AGMA) is the premier authority on gear standards, including design, testing, and performance. AGMA establishes industry benchmarks and contributes to setting American ISO standards for gear products. Other key organizations include ISO (International Organization for Standardization), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Regardless of your industry or specific application needs, choosing AGMA-certified gears ensures superior quality, reliability, and regulatory compliance.

Wondering which standards apply to your operation? Consult an industrial gear supplier for guidance on standards, certifications, and industry best practices.

How to Find the Right Industrial Gear Manufacturer

The market is flooded with industrial gear manufacturers, each vying for your attention. While there are many excellent options offering precision engineering and custom solutions, others may fall short on quality or after-sales support. This makes the search for the right industrial gear supplier confusing and overwhelming. To simplify your decision, we’ve curated a list of top-tier industrial gear manufacturers you can trust.

What should you look for in an industrial gear manufacturer? Consider the following decision factors:

- Experience and reputation: Look for manufacturers with a proven track record in your industry or application.

- Customization capabilities: Can the supplier design custom gears to match your specifications and operational requirements?

- Material and quality standards: Do they offer AGMA, ISO, or industry-compliant products?

- Lead times and delivery: Can they meet your project timeline and provide reliable logistics support?

- Technical support and after-sales service: Are engineering consultations, installation guidance, and maintenance services available?

- Pricing and warranty: Do they offer competitive pricing and comprehensive product warranties?

To streamline your selection process, start by creating a detailed list of your requirements, including budget, required gear type, operating conditions, and delivery preferences. Next, explore the industrial gear companies listed on this page and identify three to four that seem to best match your needs. Contact each manufacturer to discuss your project in detail, request technical datasheets, and ask for references or case studies relevant to your application. After these conversations, compare and contrast the insights you gathered. Finally, choose the manufacturer that offers the best balance of expertise, value, and confidence.

Ready to take the next step? Request a quote or schedule a consultation with top-rated industrial gear manufacturers today.

Looking for complementary manufacturing solutions?

Check out our Roll Forming website for metal forming expertise and our Die Castings website for precision cast components.

Still have questions about industrial gears, gearboxes, or power transmission systems? Browse our knowledge base or contact an expert for tailored advice on gear selection, industrial applications, maintenance, standards, and custom solutions.

What are the typical applications of industrial gears?

Industrial gears are widely used in automotive manufacturing, aerospace engineering, railway systems, heavy equipment, mining, transportation, food and beverage production, energy, and material handling. They adjust speed, power transmission, and manage motion in systems like cars, airplanes, conveyor belts, wind turbines, and packaging machinery.

What are the main types of industrial gears?

Common types of industrial gears include spur gears, gear sprockets, planetary gears, spline gears, helical gears, rack and pinion gears, worm gears, differential gears, bevel gears, and hypoid gears. Each type is designed for specific functions and operating environments.

What factors are important in industrial gear design?

Key factors include the number of teeth, gear module, pitch diameter, pressure angle, gear ratios, materials, and production techniques like hobbing or grinding. Designers also consider operating temperature, lubrication method, backlash, and mounting position to optimize gear performance, durability, and noise levels.

How do you calculate gear ratio and why is it important?

Gear ratio is calculated by dividing the number of teeth on one gear by the number of teeth on its mating gear. For example, a gear with 60 teeth meshing with one with 30 teeth has a ratio of 2:1. Gear ratios determine speed and torque transfer, critical for applications needing precise motion control such as automotive transmissions and conveyor systems.

What are the differences between straight and spiral bevel gears?

Straight bevel gears have straight teeth and are simpler to manufacture, making them suitable for low-speed applications but are more prone to noise and vibration. Spiral bevel gears feature curved teeth, provide quieter and smoother operation at higher speeds, handle greater loads, but require more complex manufacturing and are not interchangeable.

How should industrial gears be maintained for maximum lifespan?

Proper maintenance includes reading all manufacturer documentation, limiting exposure to dust and fluid, ensuring proper lubrication, avoiding overheating, and performing regular inspections. Using recommended lubricants and monitoring gear performance help reduce wear and extend lifespan.

What standards should industrial gears comply with?

Industrial gears should comply with standards set by organizations such as the American Gear Manufacturers Association (AGMA), International Organization for Standardization (ISO), Deutsches Institut für Normung (DIN), and Japanese Industrial Standards (JIS). Food industry gears in the U.S. also require FDA approval for sanitary design and materials.

What should I look for in an industrial gear manufacturer?

Choose a manufacturer with industry experience, strong reputation, customization abilities, adherence to quality and safety standards (such as AGMA or ISO), reliable lead times, responsive technical support, and competitive pricing with solid warranty terms.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services