In the food processing, textile manufacturing, clock making, heavy industrial mining equipment, oil exploration and in countless other industries, gears make the efficient and effective operation of all kinds of equipment possible. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

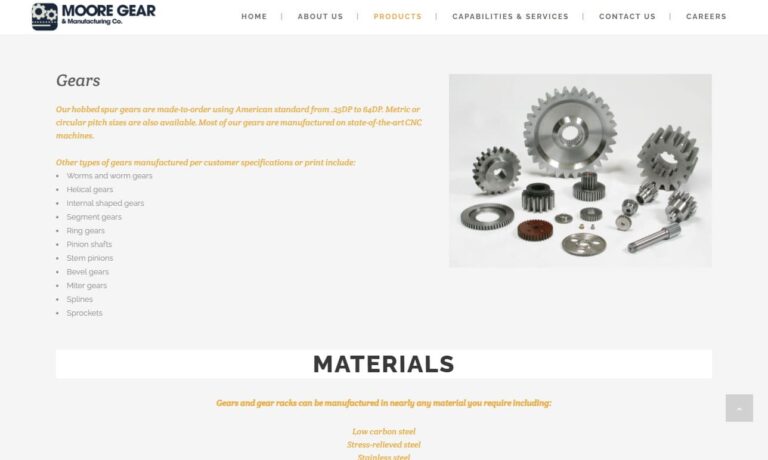

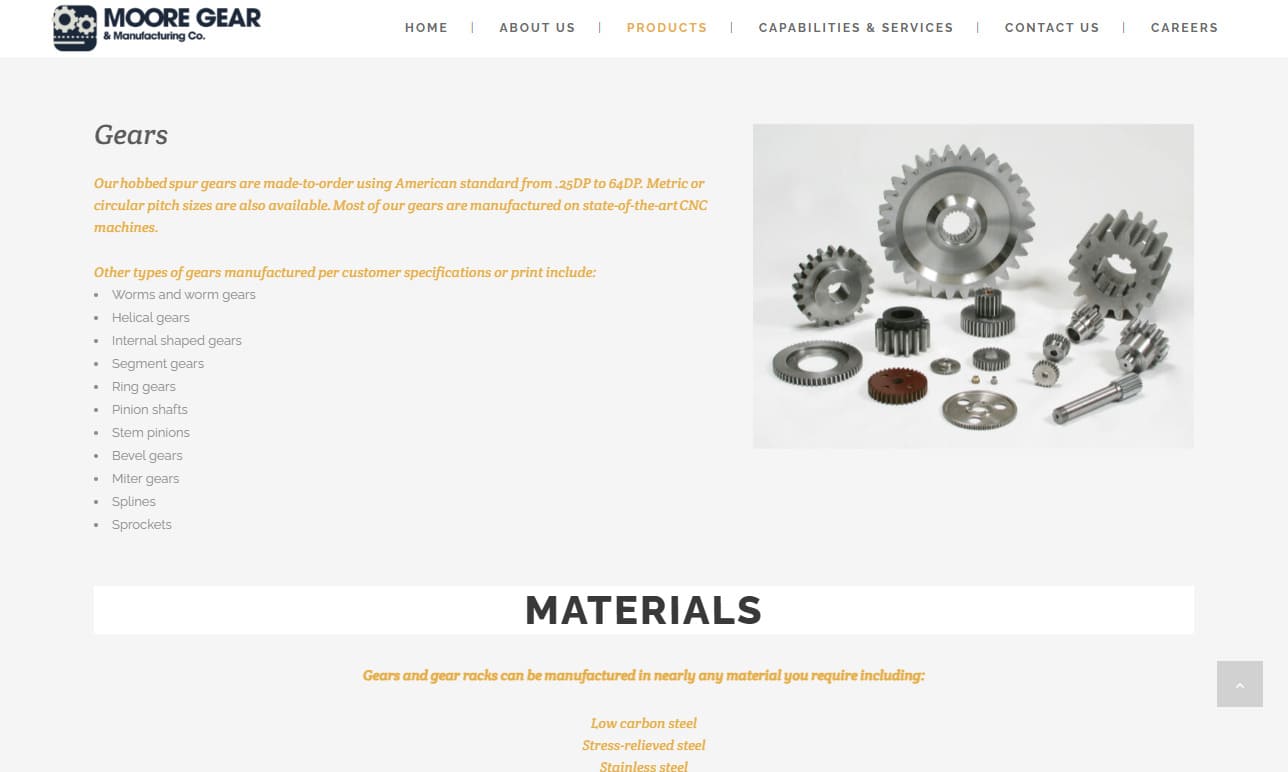

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Gear Manufacturers

Comprehensive Guide to Gear Manufacturing: Types, Applications, and Selection Criteria

Gear manufacturers play a critical role in modern industry, designing and producing a vast array of gear types for diverse mechanical and industrial applications. The field of gear manufacturing encompasses the engineering, machining, and finishing of gears to meet precise standards for strength, durability, and efficiency. Whether you're seeking to source custom gears for a specialized application or evaluating standard gear options for equipment upgrades, understanding the key gear types, their applications, and selection criteria will guide you toward optimal purchasing decisions.

What Are Gears and Why Are They Essential?

Gears are mechanical components featuring toothed wheels that interlock to transmit torque, alter rotational speed, and change the direction of motion in machinery. The strategic use of gears is fundamental in countless industries, from automotive engineering and aerospace to robotics, medical devices, and heavy manufacturing. Precision gears ensure consistent performance and reliability, making them indispensable in high-stakes environments.

Common Gear Types and Their Applications

Gear manufacturers design and manufacture an extensive variety of different gear configurations to accommodate the equally wide range of gear equipment requirements. Understanding the distinctions between gear types helps you select the ideal solution for your application.

- Bevel Gears: Bevel gears are widely used in automotive components, power tools, industrial machinery, and even automatic doors and hinges. Their cone-shaped design enables efficient transfer of motion between intersecting shafts, commonly at right angles. Bevel gear applications include differentials in vehicles and right-angle drives in conveyors.

- Rack and Pinion Gears: Rack and pinion gear systems convert rotational motion into linear motion, making them essential in steering systems, manufacturing automation, and CNC machinery. These gears are often chosen for their accuracy and reliability in moving products in manufacturing processes or controlling valves and actuators.

- Spur Gears: One of the simplest and most common gear varieties, spur gears feature straight teeth and are used in everything from children's toys and clocks to heavy manufacturing equipment and conveyor systems. Their straightforward design delivers high efficiency and ease of maintenance.

- Helical Gears: Helical gears are similar to spur gears but have angled teeth, which allows for smoother, quieter operation and higher load capacity. They are critical in automotive transmissions, printing presses, and industrial mixers.

- Planetary Gears: Planetary gear systems consist of a central sun gear, planet gears, and an outer ring gear. This configuration offers compactness, high torque density, and multiple gear ratios, making it ideal for automatic transmissions, robotics, and precision servo systems.

- Worm Gears: Worm gears provide high reduction ratios and are often used where space is limited and self-locking capability is required, such as in lifts, conveyors, and tuning mechanisms.

- Hypoid Gears: Hypoid gears are a variation of bevel gears used especially in automotive differentials for their ability to handle high torque and smooth operation.

- Plastic and Nylon Gears: Small plastic gears, including nylon and polycarbonate gears, are prevalent in consumer products like printers, electronic devices, and clocks, where low noise, lightweight, and corrosion resistance are desired.

Gear Materials: Selection and Performance Considerations

Gears may be made from a variety of materials, each selected to meet the demands of specific applications. Choosing the right gear material is crucial for optimizing durability, performance, and cost-effectiveness.

- Metals: Common metals for gear manufacturing include steel, brass, copper, aluminum, and titanium. Steel gears, often hardened or alloyed, offer superior strength and wear resistance, making them ideal for automotive transmissions, industrial gearboxes, and heavy machinery. Brass and copper gears are valued for their anti-corrosive properties and electrical conductivity.

- Plastics: Highly wear-resistant plastics such as nylon, polyacetal, and polycarbonate are useful in light-duty machinery, medical equipment, and devices where low weight, reduced noise, and corrosion resistance are required. Plastic gears are also cost-effective for high-volume applications.

- Composites: Advanced composite materials are increasingly used in aerospace and specialized industries, offering the benefits of strength-to-weight ratio, durability, and resistance to extreme temperatures or chemicals.

How to Choose the Right Gear Material?

When selecting a gear material, consider:

- Load Requirements: Will the gear be subject to high torque or heavy loads?

- Operating Environment: Is there exposure to chemicals, moisture, or extreme temperatures?

- Noise Sensitivity: Are quiet operations essential, as in medical or office equipment?

- Cost Constraints: Does the project require the most cost-efficient solution or premium performance?

- Regulatory Compliance: Are there industry standards or certifications, such as ISO or AGMA, that must be met?

Gear Cutting and Manufacturing Techniques

Gear manufacturers use advanced gear cutting and machining processes to fabricate high-precision gears. Modern gear production blends traditional craftsmanship with state-of-the-art automation to achieve tight tolerances and consistent quality.

- Gear Hobbing: One of the most versatile and efficient gear manufacturing processes, gear hobbing uses a rotating hob to cut gear teeth into blanks. It's suitable for making spur, helical, and worm gears in high volumes.

- Gear Shaping: Gear shaping employs a reciprocating cutter to generate internal and external gear profiles, ideal for complex or internal gears.

- Gear Grinding: Used for finishing hardened gears, gear grinding ensures high precision, smooth surfaces, and minimal noise, critical for aerospace, medical, and high-performance automotive gears.

- Broaching: Broaching is often used for cutting internal gear teeth or splines in a single pass, commonly applied in transmission and heavy equipment gears.

- Other Machining Processes: Gear manufacturers may also use milling, lapping, or additive manufacturing (3D printing) for prototyping and custom gear development.

What Is Gear Ratio and Why Does It Matter?

A gear's number of teeth and its specific gear ratio determine the function, speed, and control the gear will have within a larger gear assembly. Gear ratio is the relationship between the number of teeth on two meshing gears and directly impacts:

- Torque Output: Higher gear ratios increase torque, essential for heavy lifting and slow movement.

- Speed Control: Lower gear ratios deliver higher speed and are used in applications requiring rapid motion.

- Precision and Stability: Gear ratio affects system stability, noise, and efficiency, especially in robotics and automation.

Understanding and calculating the correct gear ratio is crucial to ensure the optimal performance of gear-driven systems, from industrial automation to automotive drivetrains.

Challenges in Gear System Design and Operation

Heat, vibration, and the presence of corrosive elements are all possible impediments to gear performance, which is why most gear systems use a form of lubrication. Modern gear design aims to minimize friction, wear, and mechanical losses, thereby extending the service life and efficiency of the entire system.

- Lubrication: Proper lubrication reduces friction and dissipates heat, preventing premature wear and gear failure. Common lubricants include oils and greases specifically formulated for gear applications.

- Material Fatigue: Repetitive loading can cause material fatigue, cracking, or tooth breakage—selecting the right material and heat treatment is vital for reliability.

- Noise and Vibration: Poorly designed or installed gears can lead to excessive noise and vibration. Precision machining and proper alignment are critical, especially in high-speed or sensitive environments.

- Corrosion and Contaminants: Gears exposed to harsh chemicals or moisture require corrosion-resistant materials and protective coatings.

How Can You Optimize Gear System Performance?

Successful operations employ gears that have been carefully selected after extended dialogue with gear manufacturing professionals. A gear should always be chosen with consideration for every variable that might affect its performance once employed. Consulting with experienced gear engineers and utilizing advanced simulation tools can help identify the best solution for your application.

Industrial Applications of Gears

The versatility of gears ensures their application across a multitude of industries. Some of the most common industrial uses include:

- Automotive Industry: Gears are found in transmissions, differentials, power steering systems, and electric motors, where they manage torque and speed for efficient vehicle performance.

- Aerospace and Defense: Precision gears are used in avionics, landing gear systems, navigation equipment, and weaponry, where reliability and exact tolerances are non-negotiable.

- Manufacturing and Automation: Gears drive conveyors, assembly robots, CNC machines, and other automated systems, enabling high productivity and consistent quality.

- Medical Devices: Miniature gears power imaging equipment, surgical robots, and diagnostic devices, requiring exceptional reliability and hygiene.

- Renewable Energy: Wind turbine gearboxes and solar tracking systems depend on robust gear designs to convert and control energy efficiently.

- Consumer Electronics: Small plastic gears operate in printers, cameras, and household appliances, offering quiet operation and durability.

Looking for Gears for Specialized Applications?

If you're searching for custom gear solutions or specific gear types for unique applications, reach out to gear manufacturing experts who can guide you through material selection, design optimization, and prototyping.

Key Factors in Selecting a Gear Manufacturer

Choosing the right gear manufacturer is as important as selecting the appropriate gear type and material. Consider the following decision factors when evaluating gear suppliers:

- Industry Experience: Does the manufacturer have a proven track record in your specific industry, such as automotive, aerospace, or industrial automation?

- Manufacturing Capabilities: Can the supplier produce gears to your required tolerances and quality standards, including custom designs and prototypes?

- Quality Assurance: Look for certifications such as ISO 9001 or AGMA compliance, which demonstrate commitment to quality control and process consistency.

- Engineering Support: Does the manufacturer offer design consultation, simulation, and technical support throughout the product lifecycle?

- Production Volume and Lead Time: Can the supplier handle your production volume within your required delivery window?

- Cost Competitiveness: Does the manufacturer balance cost-effectiveness with quality, reliability, and after-sales support?

What Questions Should You Ask a Potential Gear Supplier?

Before making a purchase decision, ask suppliers:

- What gear types and materials do you specialize in?

- Can you provide case studies or references from similar projects?

- What quality control processes are in place?

- How do you handle custom orders or prototyping requests?

- What are your typical lead times and production capacities?

Benefits of Working with a Reputable Gear Manufacturer

Partnering with an experienced and reputable gear manufacturer offers numerous advantages:

- Custom Engineering: Access to skilled engineers who can design bespoke gear solutions for demanding or unique applications.

- Consistency in Quality: Advanced manufacturing processes and rigorous testing ensure every gear meets or exceeds performance expectations.

- Supply Chain Reliability: Efficient logistics and inventory management minimize downtime and ensure timely delivery.

- Technical Support: Ongoing assistance with installation, maintenance, and troubleshooting to maximize gear system lifespan.

- Cost Savings: Optimized designs and efficient production methods reduce waste and lower total cost of ownership.

Frequently Asked Questions About Gear Manufacturing

- What is the difference between a spur gear and a helical gear? Spur gears have straight teeth and are easy to manufacture, while helical gears have angled teeth that operate more quietly and can handle higher loads.

- How do I select the right gear for my application? Consider factors such as load, speed, environmental conditions, required lifespan, and noise limitations. Consulting with experienced gear engineers is recommended.

- Can gears be customized for specific requirements? Yes, many gear manufacturers offer custom design, prototyping, and small-batch production for specialized applications.

- What are the signs of gear wear or failure? Common indicators include unusual noise, vibration, decreased system performance, and visible damage to gear teeth.

- How often should gears be maintained or lubricated? Maintenance frequency depends on application, operating environment, and manufacturer recommendations. Regular inspections and lubrication are essential for longevity.

Enhancing Gear System Efficiency: Maintenance and Upgrades

Maximizing your gear system's efficiency and reliability involves more than just selecting the right component. Consider these maintenance and upgrade strategies:

- Routine Inspections: Schedule regular inspections to catch signs of wear, misalignment, or lubrication issues early.

- Predictive Maintenance: Utilize sensors and monitoring tools to predict and prevent failures before they occur, reducing downtime.

- Retrofitting and Upgrades: Modernize older systems with advanced gear designs or materials to enhance performance and extend equipment life.

- Training and Support: Ensure staff are trained in proper gear handling, installation, and maintenance to avoid costly mistakes.

Ready to Source the Right Gears for Your Project?

Whether you're planning a new automation system, upgrading existing machinery, or developing a custom product, working with a knowledgeable gear manufacturer is your best path to success. Contact leading gear manufacturers to discuss your project requirements, request a quote, or seek expert advice on gear design and material selection. The right partnership can help you achieve optimal performance, reliability, and value in every gear-driven system.

Explore More Gear Manufacturing Resources

- Learn more about planetary gear systems

- Contact gear manufacturing experts for a custom quote or consultation

- Browse our resources on gear cutting techniques and best gear materials

- Discover the latest gear industry trends and innovations

Still have questions about gear manufacturing, selection, or sourcing? Contact us today—our team is ready to help you find the ideal gear solution for your application, from standard parts to custom-engineered systems.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services