Planetary gears are crucial in complex automotive transmissions, drive trains and other applications where complex gear ratios are required for smooth torque transmission. These complex and drastic gear ratios are possible since planetary gears have the ability to produce different gear ratios depending on which gear is used as the input, which gear is the output and which gear is stationary. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gears are what we do best, and we are experts in our field. We have three generations of experience backing our company, and we use all of it to benefit you in any way possible.

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

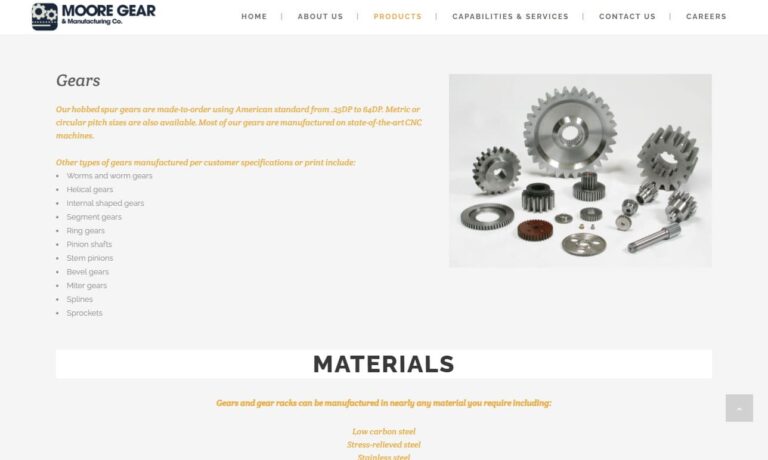

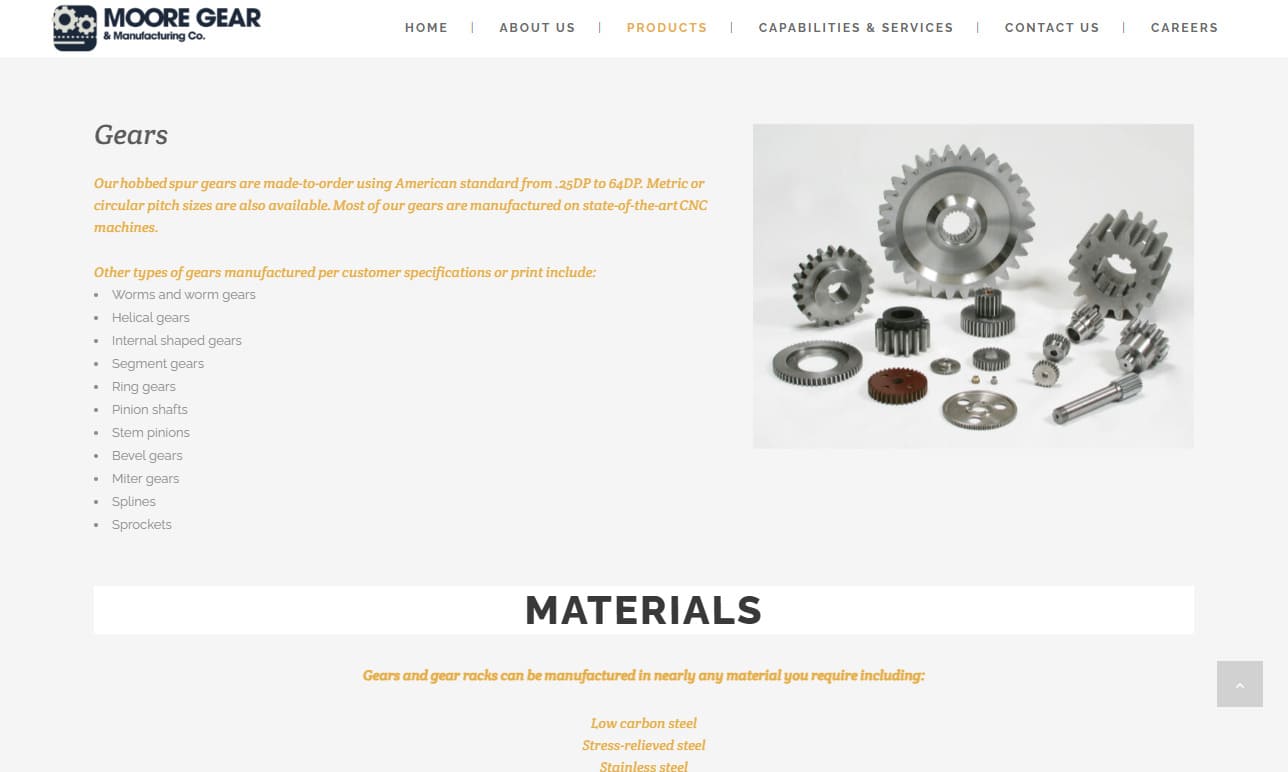

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Planetary Gear Manufacturers

Planet gears are also used in industrial automation and motion control applications such as wind turbines, bicycles, helicopters, heavy machinery, electric motors and paper feeders. Some advantages of planetary gears include high power density, increased torque capability, pure torsional reactions and large reduction in small volumes. However, there are disadvantages to using planet wheels as well, which include design complexity, high bearing loads and inaccessibility. Planetary gears are often used in industries such as marine, automotive, mining, military, commercial, construction, chemical processing, aerospace and agricultural.

Planetary gears typically come in sets of two or more that operate on or inside larger industrial gears; these are referred to as planetary gear systems. In a planetary gear system the exterior gears interlock with the inward-facing teeth of a larger internal gear, increasing the output speed of the large outer gear through rotational torque applied to the internal sun gear. The four main components that make up these planetary gear sets are the sun gear, the ring gear, the planet pinions and the planet carrier.

The sun gear is the center of the planetary gear system. The ring gear, or internal gear, is named due to both its shape and its internal teeth and connects the epicyclic gear set to an output shaft. The planetary pinions are gears with a small number of teeth designed to mesh with a larger wheel, which is the ring gear. Engaged simultaneously by the sun gear, each of the planetary gears applies torque to the ring gear, which in turn supplies torque to the output shaft.

The planetary pinions are attached to a rotating plate, which is the planet carrier. In order for the planetary gear set to function, either the sun gear, planet carrier or ring gear must be held stationary. While one is held stationary, one of the remaining two components serves as the input and provides power to the system, while the other serves as the output and receives power from the system. The ratio of input rotation to output rotations depends upon two key factors: the number of teeth in each gear and which component is held stationary.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services