A gear is a circular machine element spinning with teeth that may be cut, or in the case of a cogwheel or gearwheel, they can be inserted. These teeth, known as cogs, mesh with another toothed part to transfer (convert) torque and speed. The fundamental idea underlying how gears work is comparable to how levers work. Cog is another colloquial term for gear. A power source’s speed, torque, and direction may all be altered via geared devices. As they are created for specific uses where a conventional-sized gear cannot fit, little gears are no different. Some of these include use in tiny electronics, toolkits, workout equipment, and medical gadgets. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gears are what we do best, and we are experts in our field. We have three generations of experience backing our company, and we use all of it to benefit you in any way possible.

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

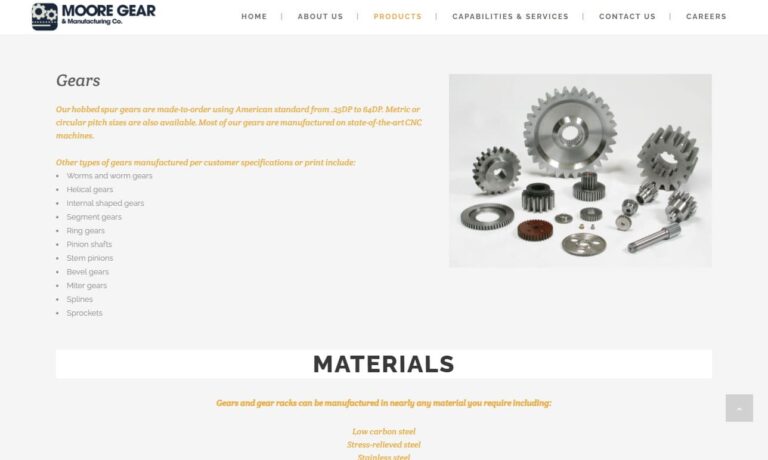

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Small Gear Manufacturers

Materials of Small Gears

Small gears, also known as miniature gears or micro gears, are precision-engineered components critical to the smooth operation of countless devices and machines. The choice of material for manufacturing small gears is a crucial decision that determines performance, durability, and suitability for specific applications in industries such as robotics, medical devices, automotive, aerospace, and consumer electronics. Selecting the optimal gear material ensures high strength, minimal wear, and reliable transmission of motion or power in compact assemblies.

The following materials are commonly employed in the creation of small gears, each offering distinct mechanical properties and advantages for various gear applications:

AVC, Nylon, Delrin (acetal), Silicon-Manganese Alloy, High-Temperature Steel, Manganese Steel, Steel, Special Bearing Steel, Aluminum, Cast Iron, 303 Stainless Steel, Molybdenum Steel, Nickel-Chromium Steel, 17-4 Stainless Steel, Carbon Steel, Chromium Stainless Steel, Chromium-Molybdenum Steel, Chromium-Vanadium Steel, Nickel-Chromium-Molybdenum Steel, and Bronze.

- Plastic Gears (Nylon, Delrin): Lightweight, corrosion-resistant, and suitable for low-noise, high-precision applications such as medical devices and consumer electronics. Plastics are ideal for small gears used in environments where lubrication is challenging or where non-conductivity is required.

- Stainless Steel and Alloy Steels: Provide exceptional strength, wear resistance, and durability, making them suitable for demanding miniature gear applications in aerospace, robotics, and industrial automation. Stainless steels also offer superior corrosion resistance for harsh environments.

- Aluminum: Offers a good balance between strength and weight, often used in small gear applications where minimizing mass is critical, such as drones and lightweight robotics.

- Bronze: Known for its low friction and excellent wear properties, bronze is used for small worm gears and applications requiring smooth, reliable operation over long service lives.

- Cast Iron: Selected for its compressive strength and vibration-dampening properties in certain instrument gear designs.

When exploring miniature gear materials, consider factors such as load capacity, operating temperature, lubrication requirements, dimensional stability, and compatibility with mating components. Are you searching for the best material for your specific miniature gear project? Contact a specialist or request a custom quote to ensure your gears deliver optimal performance and longevity.

Types of Small Gears

Small gears are classified based on several attributes, including the intended application, gear pitch (teeth spacing), and the required quality or precision. Understanding the different types of miniature gears is essential for engineers, product designers, and buyers seeking the right solution for motion control, power transmission, or timing applications in compact systems. The three major categories of miniature gears are:

- Precision or Instrument Gears: These gears feature fine pitch and small diameters (often up to 120 mm or less), making them ideal for applications demanding accurate motion transmission with minimal backlash. Precision gears are used in instrumentation, medical devices, measurement equipment, and robotics, where high indexing accuracy and tight tolerances are critical. Quality can range from basic to ultra-high precision, depending on manufacturing method and end-use.

- Low-Power Gears: Designed for moderate power transmission (from a few gfcm of torque up to around 750 W or 1 hp), these miniature gears are found in toys, small appliances, handheld tools, and light-duty industrial equipment. Low-power gears prioritize efficiency, cost-effectiveness, and reliable operation in medium-duty gear trains.

- Horological Gears: This specialized class of tiny gears powers clocks, watches, and precision timekeeping devices. Horological gears often use unique tooth profiles and ultra-fine pitches to maintain accuracy over long periods, distinguishing them from other small gear applications.

Common Small Gear Designs

- Spur Gears: The most common type, with straight teeth parallel to the axis. Used for simple, reliable transmission of motion between parallel shafts.

- Helical Gears: Feature angled teeth for smoother, quieter operation and higher load capacity in compact mechanisms.

- Bevel Gears: Used to transmit motion between intersecting shafts at various angles, frequently found in miniature drives and instrument assemblies.

- Worm Gears: Offer high reduction ratios, self-locking ability, and compact packaging for applications like small actuators and tuning devices.

- Planetary Gear Sets: Provide high torque density and precise motion control, commonly used in robotics and automated equipment.

Construction of Small Gears

Manufacturing miniature gears requires advanced engineering, specialized machinery, and strict quality control to achieve the tight tolerances and fine finishes demanded by modern industries. The construction process for small gears involves several key steps:

- Design and Prototyping: Small gear manufacturing begins with detailed computer-aided design (CAD) to ensure precise tooth geometry, optimal contact patterns, and compatibility with mating components. Rapid prototyping may be used to validate form and function before production.

- Gear Forming: This is the most widely used method for producing multiple gears of identical shape and size. Gear forming techniques include injection molding (for plastic gears), die casting (for metals), and sintering (for powdered metals), depending on the material and application.

- Gear Cutting: For high-precision and custom small gears, cutting processes such as hobbing, milling, shaping, broaching, and lapping are employed. These methods enable the creation of complex tooth profiles and extremely tight tolerances.

- Finishing and Heat Treatment: After forming and cutting, gears are finished to enhance surface smoothness and dimensional accuracy. Surface treatments like polishing, deburring, and heat treatment (such as carburizing or nitriding) may be applied to improve wear resistance and gear life.

- Inspection and Quality Control: Advanced metrology tools (e.g., coordinate measuring machines, laser scanners) are used to inspect critical dimensions and verify compliance with standards such as ISO 1328, AGMA, or DIN.

Looking for insight into the best manufacturing process for your miniature gear needs? Compare small gear fabrication methods or reach out to our technical support team for guidance on selecting the right construction technique for your application.

Working Principle of Small Gears

Understanding how miniature gears work is vital for system designers, engineers, and technicians seeking to optimize power transmission and motion control in compact mechanisms. The basic operation of small gears adheres to the same physics as larger gears but requires greater attention to precision and material properties due to the reduced scale.

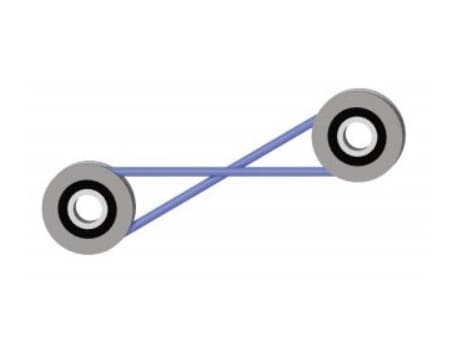

- In a setup with a small and a large gear, the smaller gear (pinion) rotates more quickly, completing more revolutions in a given time than the larger gear. This gear ratio relationship is essential for applications requiring speed multiplication or torque reduction.

- When two gears mesh, the teeth of one exert force on the teeth of the other, transmitting motion and power smoothly and efficiently.

- The line of action, determined by the contacting teeth, generates both radial and circumferential force components. The circumferential force is responsible for rotary motion, while the radial component affects shaft support and bearing loads.

- Minimizing backlash and maintaining precise tooth contact are critical for high-precision small gear mechanisms, such as those found in medical imaging devices, aerospace controls, and precision actuators.

Want to learn more about gear mechanics and motion transmission at the micro scale? Read our guide to small gear operation or ask our team about optimizing your gear train design.

Miniature Gear Specifications

Specifying the right miniature gear for your engineering project requires careful consideration of several technical parameters. Key specifications for micro gears include:

- Application Use: Small gears perform critical functions such as pumping, cutting, actuation, and precise positioning in biomedical devices, robotics, laboratory equipment, and electronic instruments.

- Number of Teeth: Miniature gears may have as few as 6-20 teeth at diameters as small as 0.05“ (1.27 mm), depending on application requirements.

- Minimum Diameter: Micro gears can be manufactured at diameters down to 0.05“ or even smaller with advanced processes.

- Diametral Pitch: Extremely fine pitches (e.g., 250 DP and above) are common, enabling high gear ratios in confined spaces.

- Face Width: Typically 0.01 inches or less, allowing integration into ultra-compact assemblies.

- Tolerances: Micro gear designs demand extremely tight tolerances, often up to +/-0.0001“, to ensure reliable, backlash-free operation in precision instruments.

- Quality Control: Manufacturing is governed by strict standards such as MIL-I-45208A, MIL-STD-45662A, and ISO 9001:2000, ensuring consistent quality for demanding applications, including military and aerospace.

- Lead Time: Standard production lead times for custom miniature gears typically range from 6-10 weeks, depending on complexity and material selection.

Advantages of Small Gears

Miniature gears offer a range of compelling benefits that make them indispensable in advanced engineering, precision manufacturing, and compact device design. Key advantages include:

- Optimized for Low Torque Applications: Small gears excel in scenarios where less torque is needed, such as instrumentation, sensors, and micro-actuators.

- Reduced Gearbox Ratios: Enable cost savings by minimizing the need for large, expensive gearboxes while still achieving desired speed or torque outputs.

- Compact and Lightweight: Their small design envelope allows for integration into space-constrained environments, reducing overall product size and weight.

- Lower Backlash: Miniature linear gearboxes benefit from reduced backlash, resulting in higher positioning accuracy and repeatability.

- Enhanced System Rigidity: Small gears enable stiffer gear trains, improving control response and vibration resistance in high-precision applications.

- Higher Resonance Frequency: Increased system resonance frequency reduces susceptibility to unwanted vibrations, especially important in aerospace and laboratory equipment.

- Noise Reduction: Fine tooth profiles and precise manufacturing processes result in quiet operation, ideal for medical, office, and consumer environments.

- Energy Efficiency: Lower inertia and reduced friction losses contribute to energy savings and extended battery life in portable devices.

Applications of Small Gears

Small gears play a vital role across a spectrum of modern industries, where compact, reliable, and precise motion control is essential. Their versatility and customizability make them the preferred choice for engineers and product developers. Typical applications include:

- Biomedical Equipment: Miniature gears are integral to infusion pumps, surgical robots, diagnostic instruments, and imaging equipment, where accuracy and reliability are paramount.

- Consumer Electronics: Used in cameras, printers, watches, and portable devices for precise actuation and smooth operation within tight spaces.

- Industrial Automation: Small gears enable precise motion control in robotic arms, conveyors, pick-and-place machines, and assembly line equipment.

- Automotive Systems: Found in sensors, actuators, electric seat adjusters, and instrument clusters, delivering compact solutions for modern vehicles.

- Aerospace and Defense: Critical for control surfaces, actuators, and instrumentation where lightweight, high-precision gears improve performance and safety.

- Medical Devices: Essential in dental tools, microfluidics, laboratory automation, and handheld diagnostic systems.

- Toys and Hobbyist Devices: Powering everything from model trains to RC cars, miniature gears deliver efficiency and durability in small-scale mechanisms.

- Precision Watches and Clocks: Horological gears maintain ultra-accurate timekeeping in both luxury and utilitarian timepieces.

Choosing the Correct Small Gear Manufacturer

Partnering with the right small gear manufacturer is pivotal for achieving your project's quality, performance, and cost objectives. The ideal supplier should offer expertise in miniature gear design, advanced manufacturing capabilities, and a proven track record in your target industry. Here are some essential steps and decision factors to consider:

- Evaluate Technical Capabilities: Review each manufacturer's expertise in custom gear design, prototyping, and high-precision manufacturing processes such as hobbing, molding, or EDM (Electrical Discharge Machining).

- Inspect Quality Certifications: Ensure compliance with industry standards such as ISO 9001, AS9100 (aerospace), or FDA (medical devices) as required for your application.

- Review Application Experience: Choose suppliers with demonstrated experience in your sector, whether biomedical, aerospace, automation, or consumer electronics.

- Assess Material and Process Range: Leading miniature gear manufacturers offer a broad range of materials (plastics, metals, specialty alloys) and can advise on the best fit for your application.

- Request Prototypes and Samples: Evaluate sample parts for dimensional accuracy, surface finish, and performance under load before committing to full production.

- Compare Lead Times and Pricing: Request detailed quotes and timelines using our directory and RFQ (Request for Quote) tools to ensure the best value and timely delivery.

- Direct Communication: Make use of our directory to contact manufacturers directly, ask technical questions, and clarify project requirements for a seamless procurement process.

To ensure you have the most productive outcome when purchasing small gears from a small gear manufacturer, it is important to compare several companies using our comprehensive directory of small gear manufacturers. Each small gear manufacturer has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each small gear business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple small gear companies with the same form.

Ready to find your ideal miniature gear supplier? Request a quote now or consult our procurement team for tailored recommendations based on your technical and commercial requirements.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services