Sprockets are very important mechanical components. As the most common part used in conjunction with sprockets, chains can be defined as a series of joined (typically metal) links, flexible in only one direction and used to transfer power in machinery through enmeshing with the machine’s sprockets. Industrial manufacturing is one of the more common industries that benefit from sprockets. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gears are what we do best, and we are experts in our field. We have three generations of experience backing our company, and we use all of it to benefit you in any way possible.

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

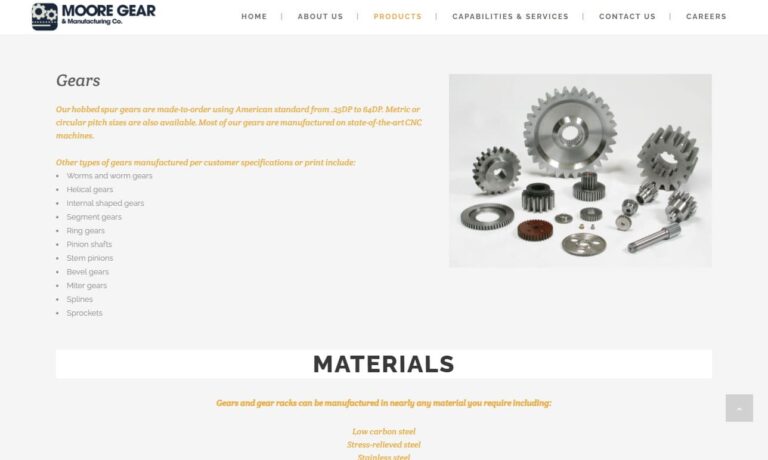

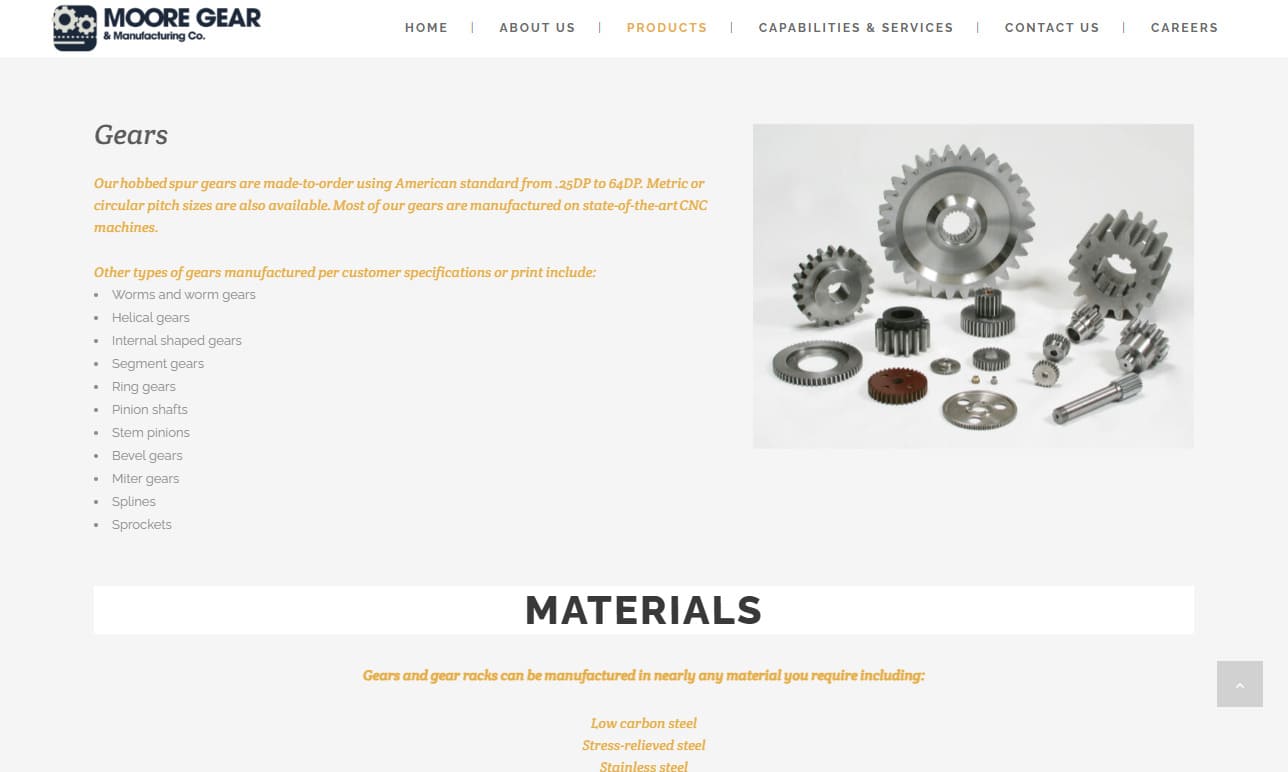

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Sprocket Manufacturers

However, additional industries include automotive, for power transmission applications; agriculture and forestry, in various types of equipment; film and paper, for film transport mechanisms found in move projectors and cameras; and electronics, for computer printers and electric motors.

Sprockets are made from a wide range of materials: stainless steel, which works best for high temperature and food processing applications; cast iron, most often used with flat wire conveyor belts; and plastics such as nylon, polyethylene and polyurethane, which allow for continuous use at high temperatures.

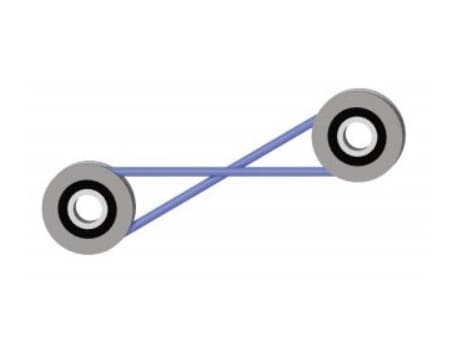

Sprockets are formed in much the same way as gears, through cutting techniques such as hobbing, so that they are able withstand harsh and repetitive use. Sprocket hobbing is the process of using a broaching machine to cut the grooves, known as teeth, into a component. Capable of cutting sprockets with different numbers and varying sizes of teeth, sprocket hobbing is used to make teeth for many different kinds of sprockets. Additional machining processes are used, such as drilling, in order to ensure the best teeth and closest tolerances. Secondary service including heat treating and hand finishing can be used in order to provide additional strength and quality. Often cut in both English and metric dimensions, there are many different types of sprockets available including idler, roller chain, split, timing belt and film.

Idler sprockets are used to prevent whipping action and to help obtain optimum chain tension in power transmissions. Also useful in power transmission, roller chain sprockets are light-weight, durable and often used for precision equipment components. Split sprockets, on the other hand, are useful in applications requiring detachment without having to dismantle machinery. Timing belt sprockets are also referred to as synchronous sprockets and provide timed, non-slip power transmission. Film sprockets refer to the type of sprocket used to move film through various machines by engaging with holes located along the two sides of the film strip.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services