The spur gear, a toothed component with a cylindrical shape, is mainly employed in industrial plants to convey mechanical motions and regulate velocity, power, and torque. These simple gears are affordable, strong, dependable, and provide a consistent positive drive to ease regular industrial activities. The most readily recognizable common gear that transfers motion between two shaft-parallel, coplanar teeth is called a spur gear. One of the most common varieties of precision cylinders is the spur gear. These gears have a straightforward design with straight, parallel teeth arranged around a cylinder body’s perimeter with a center hole that fits over a shaft. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

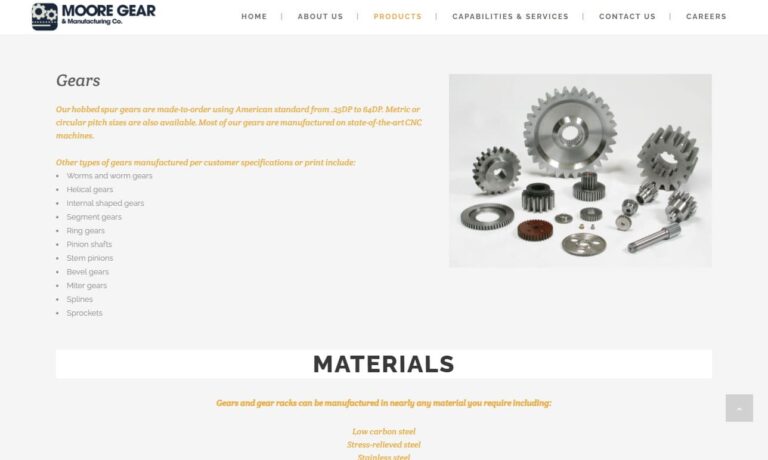

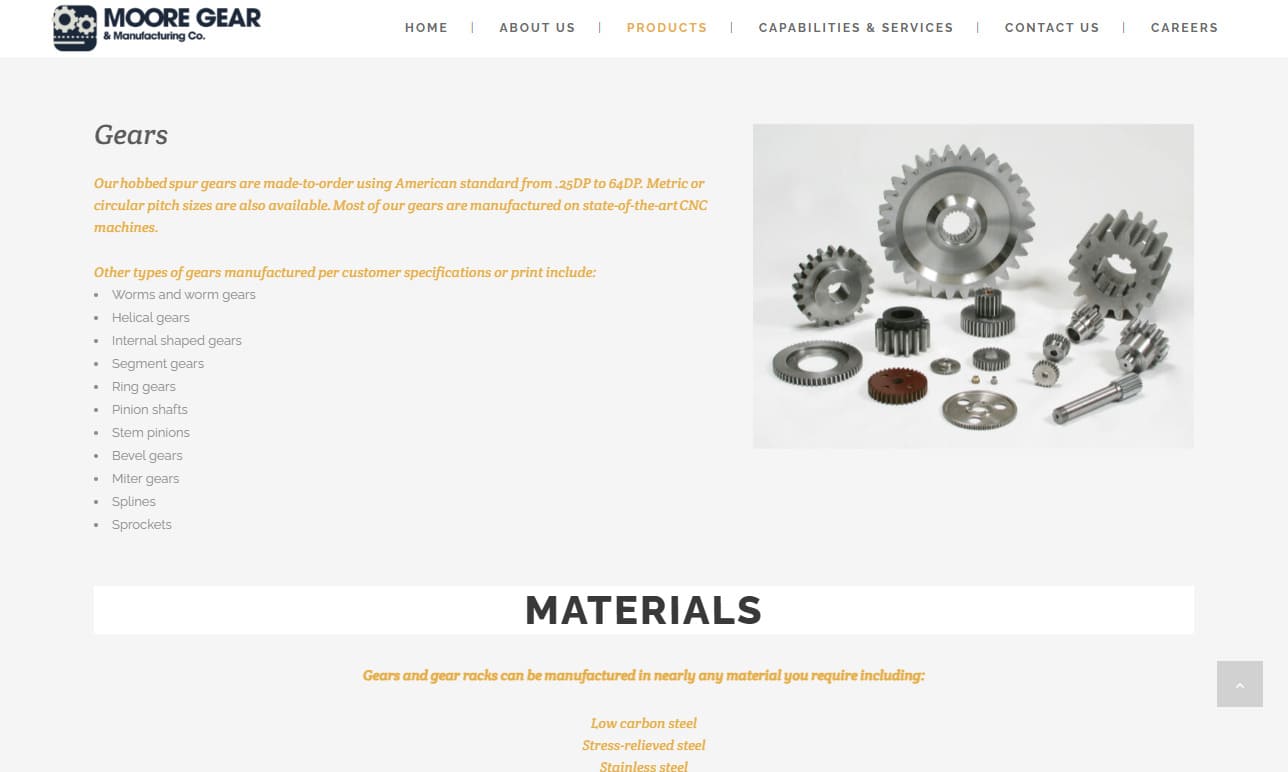

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Spur Gear Manufacturers

Spur Gear Types

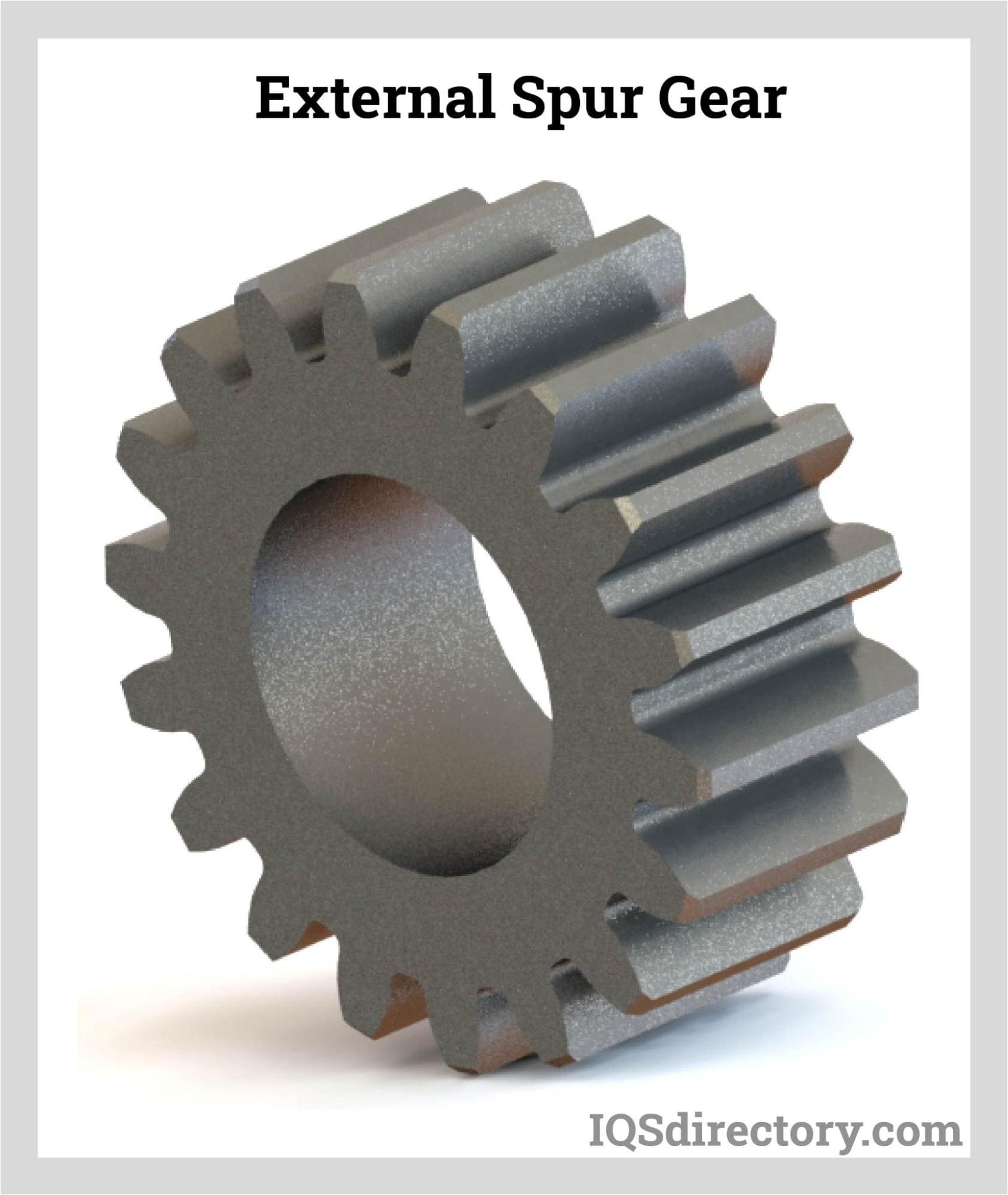

External Spur Gears

In this type of spur gear, the teeth of the employed gear are located on the surface of the cylinder, which is common in all sorts of gear configurations. As a result, the gears will revolve in the reverse direction when they mesh with another gear. Typically, the driven gear is smaller compared to the drive gear.

Internal Spur Gears

On the inside surface of the gear, teeth for an inner spur gear are carved. The exterior is smooth and shaped like an ideal oval or circle. The internal gear teeth mesh with a smaller gear or a pinion. In the same direction, the gears turn.

Pin Hub Spur Gears

A set screw is used to fasten a pin on this type of spur gear to the axle. Dowels, springs, taper pins, and rolls can all be used to fasten them to a shaft. The gear's hole is precisely drilled to the pin's size for a tight connection. To prevent it from losing grip and slipping into the machine, the set screw that was used to secure the gear onto the axis is removed. The dimension of the bore where the gear links to the shaft determines how the various spur gear types differ.

Spline Spur Gears

When using spline spur gears, grooves or teeth are cut into the driving shaft to match the grooves in the spur gear's bore. Spline configurations come in various shapes, some straightforward and others are complicated. The gear's design affects how far apart the splines are spaced. Spur gears with an involute spline can have up to 32 teeth.

Manufacturing Spur Gears

Cutting, casting, powder forging, computer numeric controlled (CNC) machining, and metallurgy production are just a few of the processes utilized to make spur gears. Regardless of manufacturing technique, dimensional precision and respect for tolerances are essential since even the smallest mistake can prohibit the proper gear meshing. Spur gears are cut, formed, or machined when extreme performance is required. Whatever the cutting method, it all starts with a blank piece of gear. The kind of material used to create the gear blank determines the spur gear's quality. Only high-quality materials, such as a pie-shaped billet, can be used to create high-quality spur gears.

Spur Gear Applications

Below is a partial list of spur gear applications.

- Spur gears can be employed to change the speed at which an object travels.

- Spur gears are usually employed to modify the power of a particular object.

- In a mechanical structure, these gears transmit force and motion from a single shaft to another. Washing machines, tumble dryers, construction equipment, gasoline pumps, and mills all use spur gears for this reason.

- The conversion of a source of energy, such as water or wind, into electrical energy, takes place at power plants using so-called "trains" of spur gears. Where being loud is not an issue, spur gears are frequently employed in ball mills, crushers, trains, bicycles, and aviation engines.

- A pair of spur gears in a road roller converts the fast engine rotational speed into a slow rotor velocity for the wheels. A road roller can move its massive roller thanks to this modification.

- Due to a sports car’s lightweight, less rotational force is required for the wheels to turn. Spur gears, which propel sports cars, convert the engine's velocity into a slower wheel rotational speed. With less turning force, the wheels are capable of rotating more quickly.

Factors to Consider When Choosing a Spur Gear

- Speed and Torque: When choosing the right spur gear, the speed and torque of a system must be calculated. In addition to the outgoing speed and torque, this also applies to the supply speed and torque.

- Gear Teeth: Gear teeth design is influenced by the teeth’s pitch, depth, and pressure angle. Calculating teeth geometry requires the use of a complicated set of formulas.

- Idler Gear: It is important to know if an idler gear is needed when designing spur gears.

Choosing the Right Spur Gear Supplier

To ensure you have the most constructive outcome when purchasing spur gears from a spur gear supplier, it is important to compare several companies using our directory of spur gear suppliers. Each spur gear supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each spur gear business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple spur gear companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

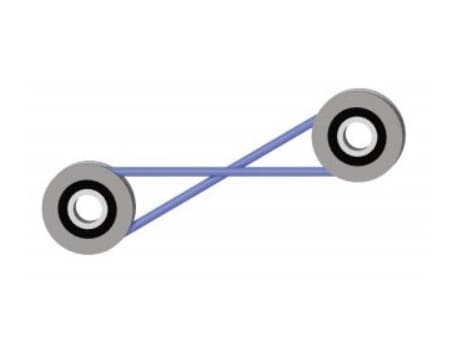

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services