Gears are crucial in many mechanical systems, from simple machines like bicycles to complex devices like aircraft engines. Worm gears are a type of gear system with a unique design and functionality. Worm gears have a high gear reduction ratio, so they can easily transfer high torque loads. Read More…

Omni G & M Corporation is a leading gear fabricator specializing in precision machined and custom solutions in a variety of sizes and types. Please check out Omni G & M’s website or call a friendly personnel member today!

Gear Motions is a leading gear manufacturer specializing in supplying custom cut and ground gears. Our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

Manufacturing industrial and commercial gears is what Houston Gear USA does. We produce gears from 1 3/4 DP – 200 DP in a choice of materials. Choose from spur gears, custom gears, helical gears, double helicals, splines, straight bevel gears, worm gears, sprockets, and herringbone gears.

At Ascent Precision Gear Corporation, we focus on manufacturing high-precision gears that support smooth, reliable power transmission in demanding mechanical systems. We engineer our gears to meet exacting tolerances for strength, accuracy, and durability, using carefully controlled processes that ensure consistent performance under load.

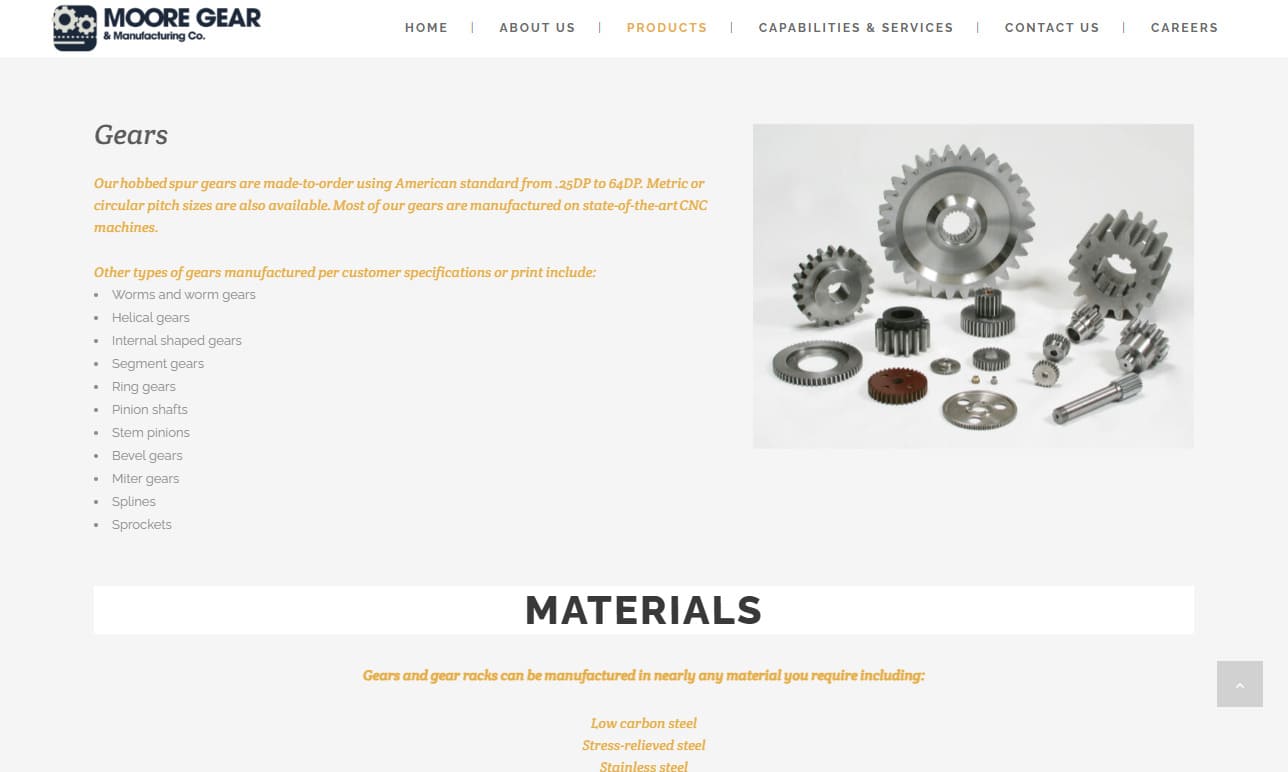

At Moore Gear & Manufacturing Co., Inc., we focus on producing precision gears that support reliable power transmission and smooth mechanical performance across demanding industrial applications. We manufacture our gears with close attention to material quality, machining accuracy, and tooth geometry to ensure strength, consistency, and long-term durability.

At Brewer Machine & Gear Co., we specialize in manufacturing precision gears that deliver dependable performance for industrial power transmission and motion control applications. We engineer our gears with careful attention to material selection, tooth geometry, and machining accuracy, ensuring reliable operation under demanding loads and operating conditions.

More Worm Gear Manufacturers

Components of Worm Gears

Worm gears have several components, including the worm, the worm wheel, thrust bearings, lubrication, cooling systems, and housing. The worm is the primary driving component that transfers power to the worm wheel. The worm wheel meshes with the worm to transmit motion. Thrust bearings support the worm wheel and reduce friction, while lubrication and cooling systems reduce wear and heat generation. The housing encases the worm and the worm wheel and provides support.

Types of Worm Gears

Worm gears come in different sizes and materials, depending on their intended application. For example, large worm gears are used in heavy-duty machinery like mining equipment, while small worm gears are used in precision instruments like clocks and watches. The materials used to manufacture worm gears vary from cast iron to high-strength alloys like steel and bronze. The choice of material depends on factors like strength, durability, and cost.

Considerations Regarding Worm Gears

While worm gears have several advantages, there are some things to consider regarding worm gears. For example, they are less efficient than other gear systems because of the sliding action between the worm and the worm wheel. This sliding motion generates heat and results in power loss. Worm gears are expensive to manufacture, and they have limited size ranges and power transfer capabilities. Maintenance of worm gears can be challenging, especially in hard-to-reach areas.

Advantages of Worm Gears

Despite their limitations, worm gears have several advantages that make them ideal for specific applications. For example, their high gear reduction ratio makes them ideal for high-torque applications like heavy machinery. Their self-locking feature makes them useful in safety-critical applications like lifts and cranes. Worm gears have a compact design, which saves space in machines with limited space. They also operate quietly, which reduces noise pollution, and they have a longer lifespan compared to other gear systems.

Applications of Worm Gears

Worm gears are widely used in various industries due to their unique design and functionality. Let's take a closer look at their applications in different fields.

Industrial Machinery

Worm gears are used in many industrial machines, including conveyor systems, rolling mills, printing presses, and cranes. In conveyor systems, worm gears transfer heavy loads from one point to another. Worm gears create a smooth, precise motion in rolling mills, which are used to shape and convert metals into finished products. They are also used in printing presses to transfer the ink onto paper and other surfaces, and in cranes, they provide smooth and accurate movement of the loads.

Automotive Industry

In the automotive industry, worm gears are used in steering systems and transmissions. In steering systems, they provide a high level of precision and control over the vehicle's direction, while in transmissions, they provide a high gear reduction ratio, which is essential for smooth gear shifting.

Aerospace and Defense Applications

Worm gears are also used in aerospace and defense applications, such as actuators and guidance systems. Actuators convert electrical or hydraulic energy into mechanical energy to move different parts of an aircraft, while guidance systems provide precise control over the direction and altitude of the aircraft.

Medical and Scientific Equipment

Worm gears are used in medical and scientific equipment, such as robotic surgery systems, laboratory equipment, and scientific instruments. In robotic surgery systems, worm gears provide precise and smooth motion control, while in laboratory equipment and scientific instruments, they provide accurate and controlled movement of different components.

Consumer Products

Worm gears are also used in various consumer products, such as power tools, home appliances, and toys. In power tools, they provide a high level of torque and control over the motion, while in home appliances like washing machines, they provide precise and controlled movement of different parts.

Apart from these applications, worm gears are present in textile machinery, marine equipment, and renewable energy systems. In textile machinery, they provide precise and consistent motion control for weaving, spinning, and winding processes. In marine equipment, worm gears are in steering systems and propulsion systems. In renewable energy systems like wind turbines, worm gears provide a high gear reduction ratio to efficiently convert wind energy into electrical energy.

Choosing the Right Worm Gear Supplier

To ensure you have the most constructive outcome when purchasing worm gears from a worm gear supplier, it is important to compare several companies using our directory of worm gear suppliers. Each worm gear supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each worm gear business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple worm gear companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

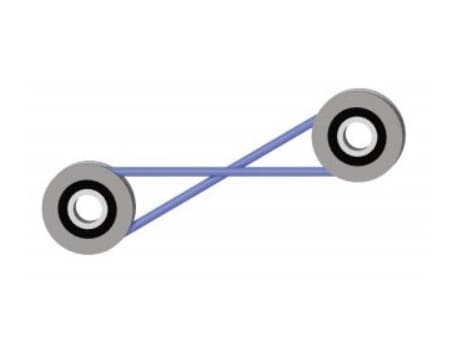

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services